Analysis we conduct is based on our many years as scientists

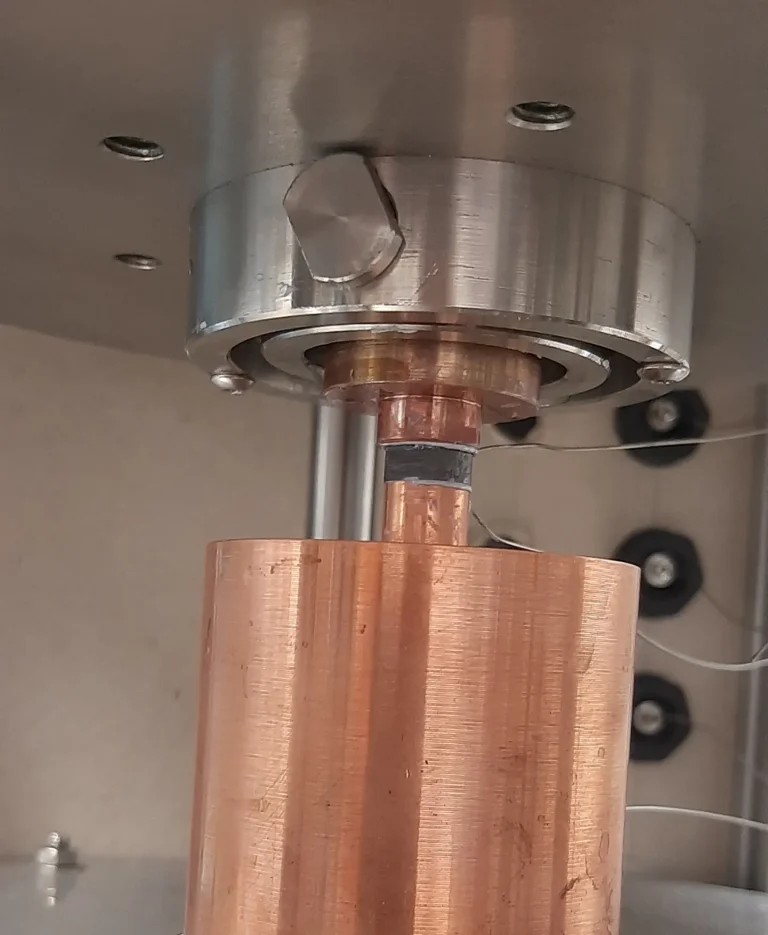

Sample requirements:

1. The solid sample should be a cylinder

d = 9 - 11 mm, h = 1 - 10 mm.

Non-parallelism of up to 5 degrees is acceptable.

2. Liquid, gel or powder portion to measure is

0.5 ml.

Thermal conductivity coefficient measurements

Inomorph Ltd. scientists can measure the thermal conductivity of solids, powders, liquids, and gels using the unique apparatus InoTherm.

The InoTherm advantages:

- Direct measurements: the heat transfers your material in natural conditions.

- Data reliability and precision: the direct measurements have an error not exceeding 3% at k = 0.05 ÷ 1 W/m∙K, 2% at k = 5 ÷ 150 W/m∙K, and 4% at k = 200 ÷ 500 W/m∙K; the data acquired with InoTherm has been published in Q1 materials science journals.

- Low sample requirements: Only rough polishing of the solid sample faces is needed; non-parallelism of sample faces is acceptable. The sample volume is just 0.1 ÷ 0.8 cm3, which is important for expensive materials.

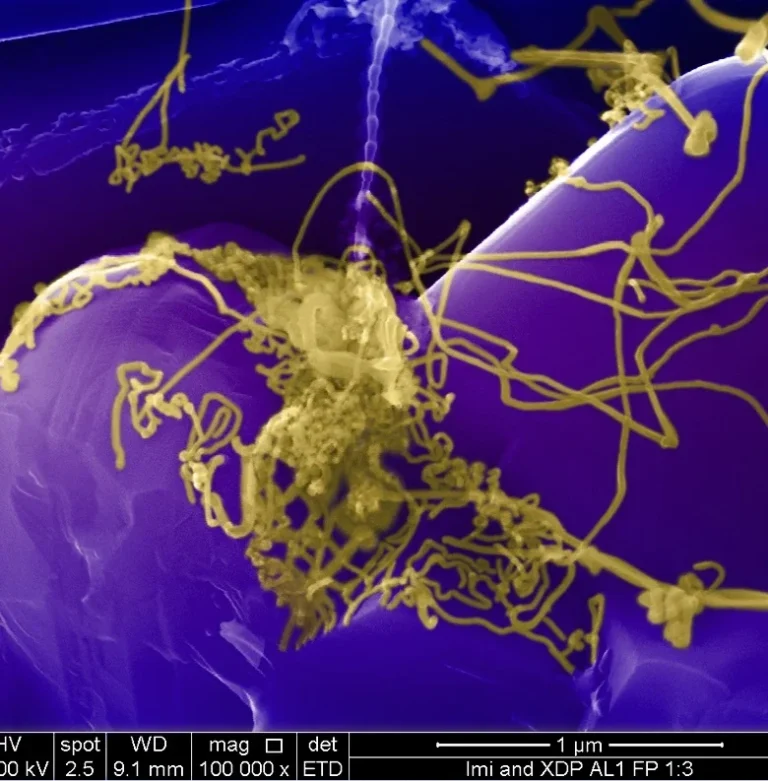

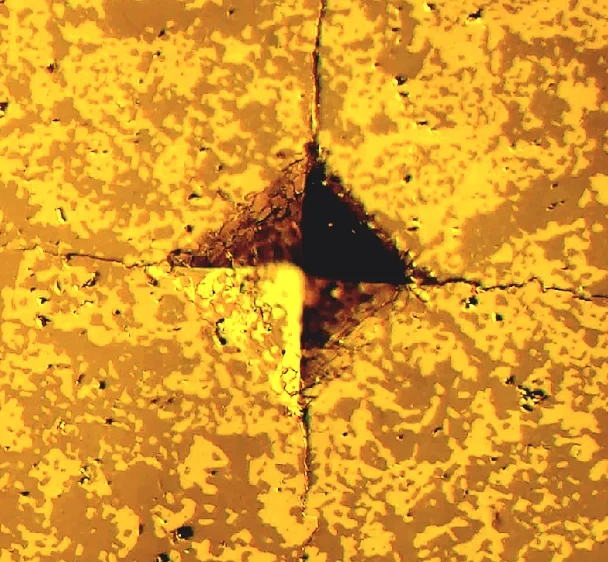

Scanning Electron Microscopy

(SEM-EDX analysis)

We can analyze the microstructure and composition of your materials with SEM-EDX methods, providing you with the report and qualified images of your sample.

On the right: an image of B-Si-C fibers in TiB2-SiC matrix. Magnification x100,000.

Published in: Popov O., Avramenko T., Vishnyakov V. Thermal conductivity and thermal shock resistance of TiB2-based UHTCs enhanced by graphite platelets // Materials Today Communications – Vol. 26 – 2021. – P. 101756. https://doi.org/10.1016/j.mtcomm.2020.101756

Mechanical testing

We can measure Vickers' hardness, indentation toughness, and thermal shock resistance of solids.

We can also advice on how to adjust your material.

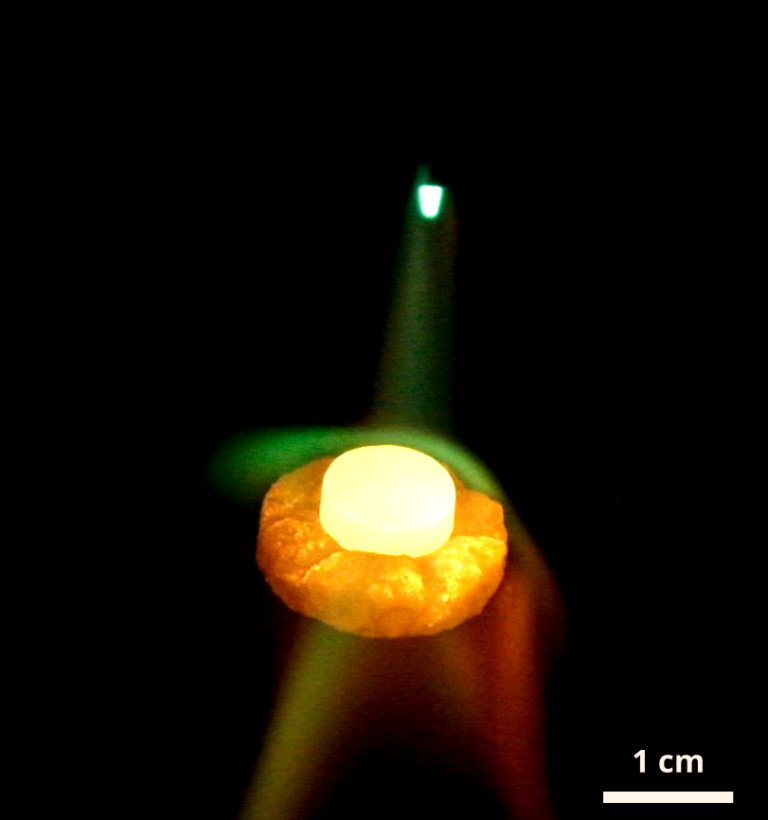

Ablation resistance testing

Inomorph Ltd. specialists can assess the ablation resistance of your materials. Are you going to use your products in severe conditions?

Let's test it!

Please contact us to learn more about our materials

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.