Thermal Conductivity & Thermoelectricity Analysis

InoTherm ®

thermal conductivity meter

The thermal conductivity coefficient is directly measured

Accurate thermal conductivity coefficient values

errors for thermal conductivity coefficient not exceeding

3% at k = 0.05 ÷ 1 W/m∙K,

2% at k = 5 ÷ 150 W/m∙K,

4% at k = 200 ÷ 500 W/m∙K.

Versatile Thermal Conductivity meter

- Measure the Thermal Conductivity Coefficient of solids, liquids, powders, and pastes with InoTherm

- A sample to measure is the size of a bean!

- Measure the Seebeck Coefficient and the Thermal Conductivity Coefficient simultaneously with InoTherm-S

Cost-efficient thermal conductivity measurements

- Small samples

Measured samples are discs with diameters from 8mm and heights from 0.5 mm or similar volumes of liquid or paste.

- Artless sample preparation

No polishing is required; the sample faces non-parallelism of up to 5ᵒ is allowed.

- Short measuring time

7-minute measuring process with an instant thermal conductivity and thermoelectricity calculation.

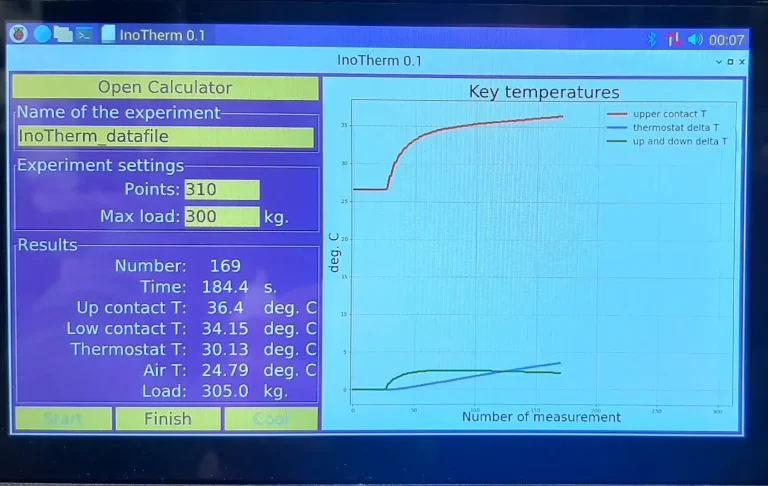

Thermal conductivity meter electronic system stability

The thermal conductivity meter has a self-contained electronic system that operates the device and calculates the thermal conductivity coefficient and Seebeck coefficient. It does not depend on other hardware and software packages.

Standard samples for the thermal conductivity coefficient measurements

Our standard samples are cylinders with a diameter between 8 and 12 mm and a height between 0.1 and 12 mm. The cylinder bases should be plain and smooth. The non-parallelism of up to 5 degrees between the faces is acceptable.

If you need, we can adjust our instrument for other sample sizes. Just contact us!

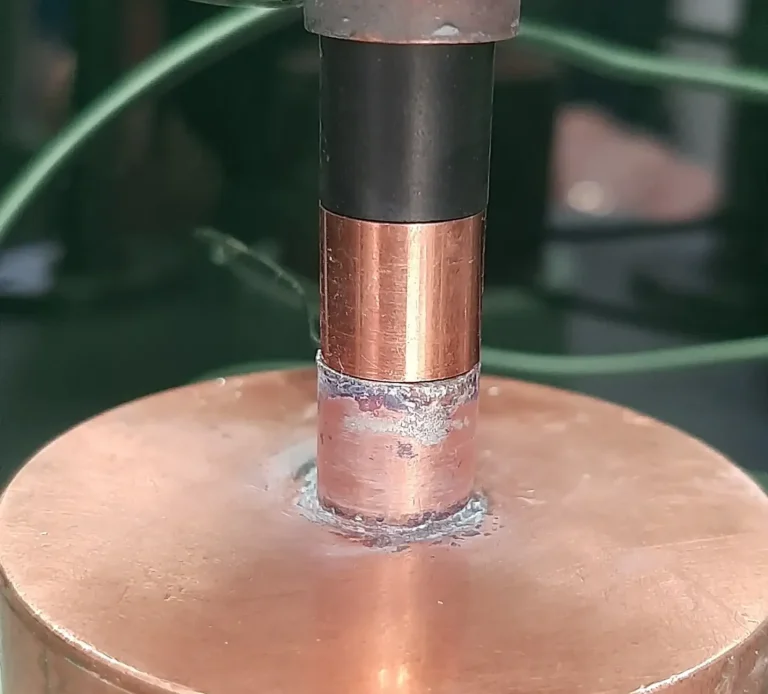

The InoTherm can now measure thermal conductivity of foils!

The thermal conductivity coefficients of 110 µm and 7,5 µm thickness of copper and aluminium foils were measured using the InoTherm thermal conductivity meter. The pieces in the picture were all we needed to measure the foils' thermal conductivity. The InoTherm results were 225 ± 8 W/mK for aluminium foil and 403 ± 15 W/mK for copper one.

Why choose the InoTherm?

- Direct measurements: The thermal conductivity of your material is measured in the most natural conditions of direct heat transfer.

- Easy to use: 7 min to obtain the thermal conductivity, k, value.

- Data reliability and precision: The direct measurements of thermal conductivity have an error not exceeding 3% at k = 0.05 ÷ 1 W/m∙K, 2% at k = 5 ÷ 150 W/m∙K, and 4% at k = 200 ÷ 500 W/m∙K; the data acquired with InoTherm have been published in high rated materials science journals.

- Undemanding sample preparation requirements: The sample for the thermal conductivity measurements should be a cylinder with a diameter starting from 7 mm and a thickness between 0.5 and 10 mm. Those are the smallest samples for direct heat flow measurements of thermal conductivity in the World! Only rough polishing of the solid sample faces is needed; up to 5 degrees of sample face non-parallelism is acceptable. The sample volume is just 0.1 ÷ 0.8 cm3, which is vital for expensive materials.

- Versatility: The thermal conductivity coefficients of solids, liquids, gels, and powders can be measured. The Seebeck Coefficient and the Thermal Conductivity can be measured simultaneously with the InoTherm-S machine.

- Digital system stability: The InoTherm is governed by a Raspberry Pi controller and thus does not depend on Windows updates.

The InoTherm application areas:

- Thermal protection systems

- Thermoelectric power

- Battery systems

- Thermal insulation

- Building materials

- Polymer composites

- Thermal conductive liquids

- Thermal interface materials

- Nanocomposites

- Green Energy

- Nuclear materials

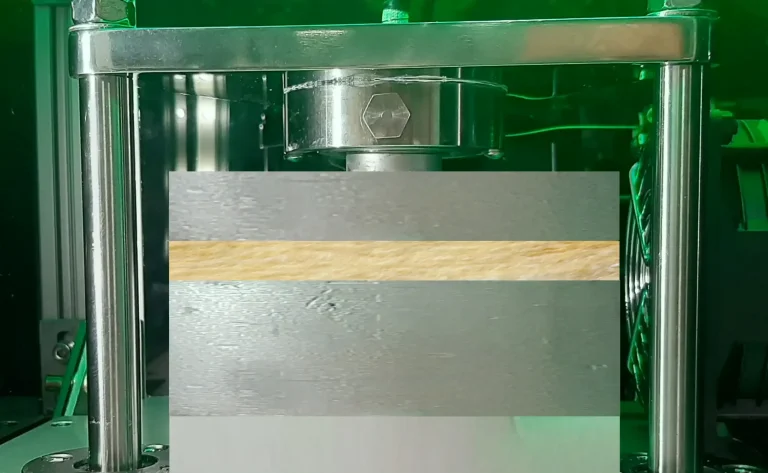

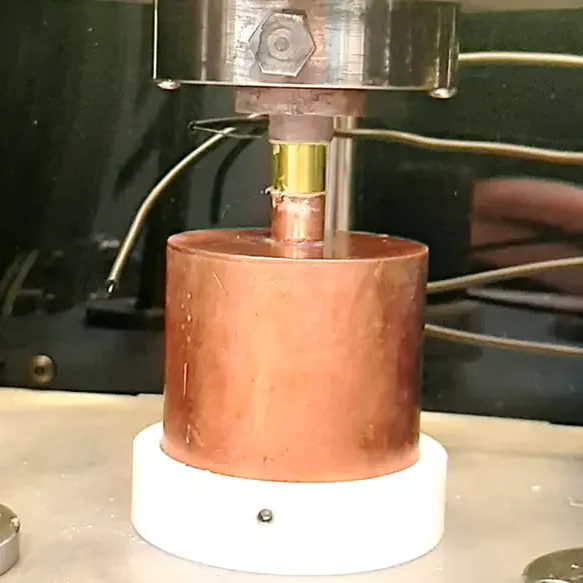

InoTherm-B

A new thermal conductivity measuring device adapted for building materials.

Explicitly developed to measure low-conductive materials with a thermal conductivity coefficient between 0.002 and 10 W/m·K with the experimental error not exceeding 2%.

Reliable measurements of thermal insulance and thermal conductivity of composite walls.

Adjustable sample shapes and sizes. Round and rectangular samples with up to 100 mm dimensions can be used to measure the thermal conductivity of building materials. The instrument can be adjusted for larger samples at the customer’s request.

The thermal conductivity coefficient of hard and soft solids, powders, pastes, and gels can be measured.

Built-in sample thickness measurements with a precision of 0.01 mm.

Controlled clumping force of up to 300 kg.

Self-contained electronic system. The instrument calculates the thermal conductivity coefficient immediately after the measurement procedure.

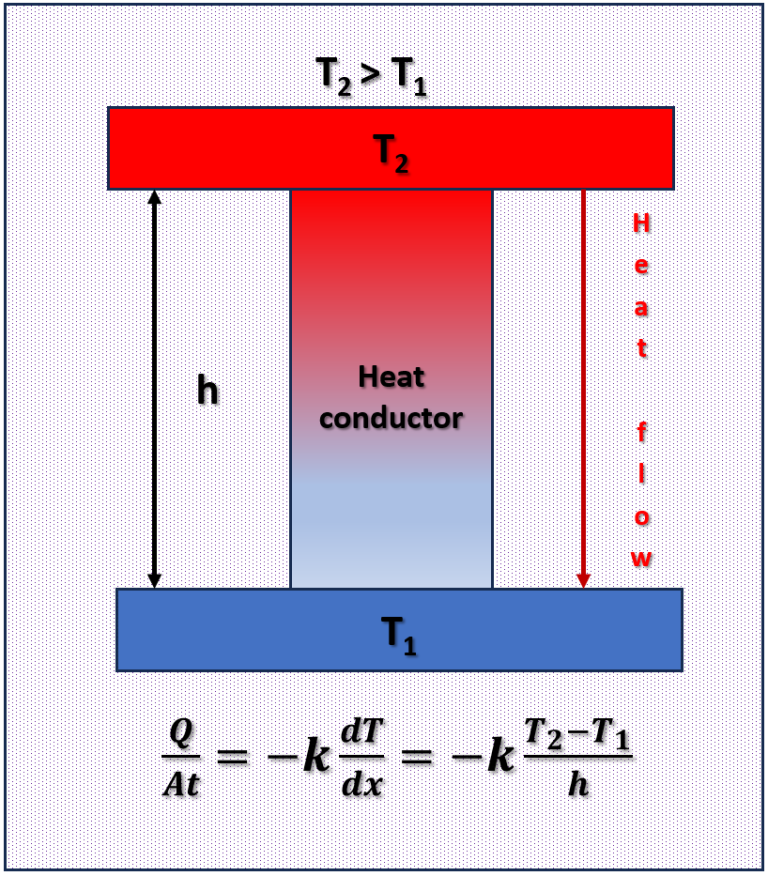

Thermal conductivity phenomenon

Thermal conductivity refers to the ability of materials to transfer heat (e.g., thermal energy) from a body with higher thermal energy (e.g., with higher temperature) to a body with lower thermal energy (e.g., with lower temperature). There are stationary and non-stationary thermal conductivity processes. The stationary thermal conductivity process occurs when the temperature difference remains constant. The non-stationary process is observed when the temperature difference changes with time.

Different thermal conductivity measuring approaches are based on stationary and non-stationary (transient) thermal processes. The stationary process instruments measure the thermal conductivity directly, while the transient methods measure thermal diffusivity and then deduce the thermal conductivity.

Quantitatively, a material's capability to transfer heat is characterized by the thermal conductivity coefficient (k), which is the amount of heat passing through the homogeneous sample of unit length and unit area if the temperature difference is 1 K. In the International System of Units (SI), the thermal conductivity coefficient is expressed as W/(m·K).

During the stationary thermal conductivity process, the energy flux density is proportional to the temperature difference (see the picture). There: Q is the energy transferred through conductor thickness h during time t via the conductor area A. The equation shows that the value of k can be obtained given the temperature difference and the amount of heat transferred via the sample with known geometry.

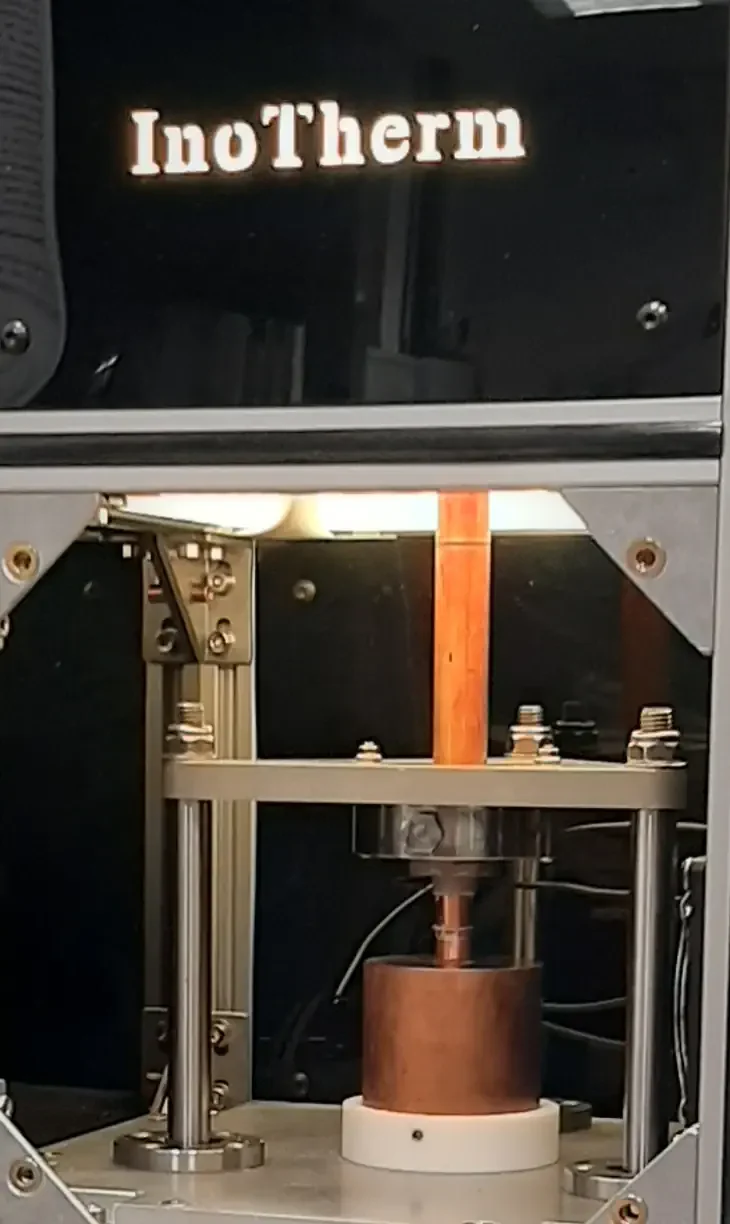

InoTherm® is a unique, new-generation thermal conductivity measuring device for quick, direct measurements of thermal conductivity coefficient. Initially designed for solids, it can also measure the thermal properties of gels, liquids, and powders.

The system measures the thermal energy that transfers from the heat source to the thermostat via the measured sample. The temperatures of the sample faces, the thermostat, and the surrounding air are precisely measured.

The raw data are presented on the screen during measurement and automatically collected into a data file. After data processing, the file also contains the thermal conductivity coefficient and the calculated error margins.

The instrument is factory-calibrated on standard samples and with all correction factors. It can be re-calibrated at the user site and by the user. The thermal conductivity measuring needs no other material parameters.

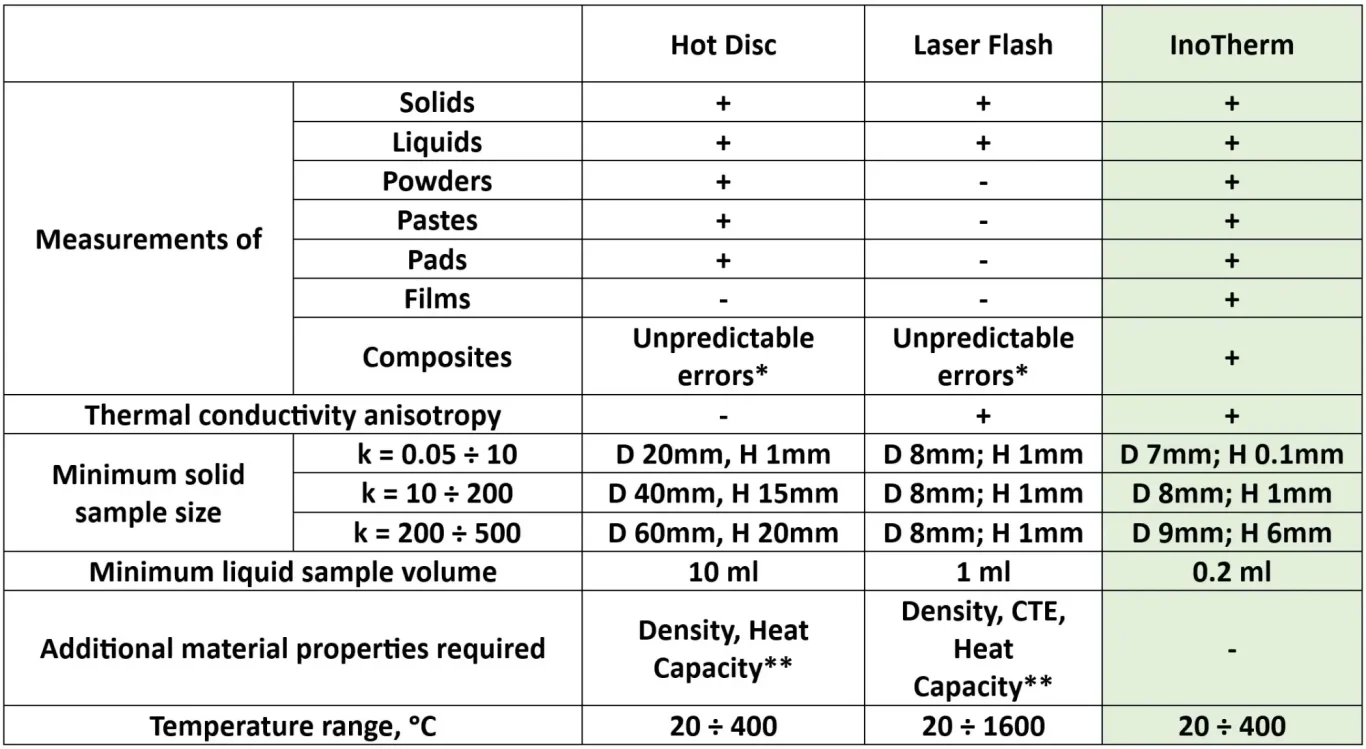

Thermal conductivity measurement techniques comparison

* The method was designed for measuring of thermal diffusivity and thermal conductivity of homogeneous and isotropic materials only. A mixture of polymer and filler is neither isotropic nor homogeneous.

** Thermal conductivity is not directly measured but calculated, requiring knowledge of other material parameters

Thermal insulance measurements

We can now measure thermal insulance (Y = ΔT/Φ): the temperature difference between two points for the unit heat flux (Φ = Q/tA) along them. Thermal insulance is especially relevant when describing the thermal resistance of the interface. It is also crucial to predict the efficient thermal conductivity of laminates. We found out that the thermal insulance of the Copper-Graphite interface is 6.5 K·mm2/W, while the same property for the 304 Stainless Steel-Graphite interface is 19 K·mm2/W. Currently, we cannot explain the difference. It is just a simple experimental fact acquired with our thermal conductivity measuring device InoTherm.

The value is essential for Li-ion battery packages and layered thermal protection systems. It can also be used for the thermal conductivity of thermoelectric composites.

The measurements were performed at a load of 30 MPa perpendicular to the contact surface. Our research is ongoing, and we invite you to follow us for more updates on thermal insulance. Fresh results will be posted soon here and on our LinkedIn page, keeping you at the forefront of this exciting field.

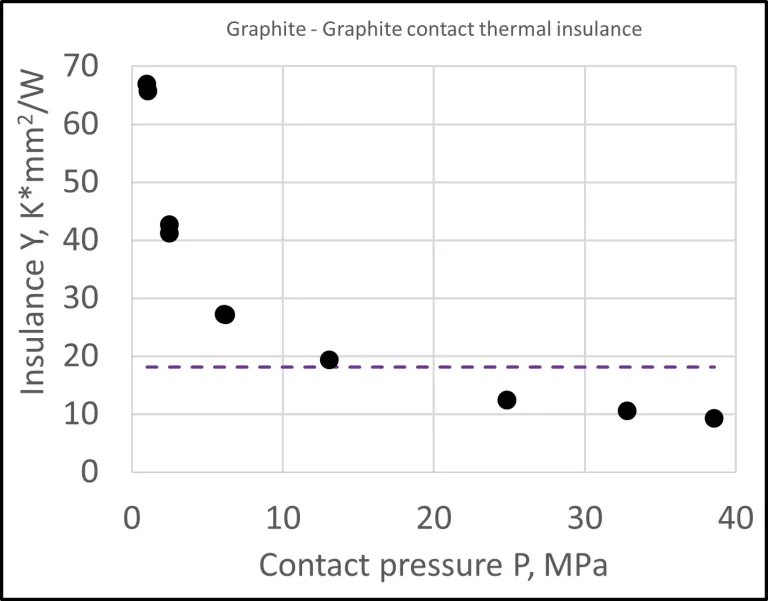

Graphite – Graphite contact thermal insulance

We measured the graphite–graphite interface thermal insulance. Here is the dependence of the insulance (we denote it as Y) on the contact normal pressure. To compare, the Y value for a 3 mm thick bulk graphite plate (k = 160 W/mK) is shown as a punctured line. So, the contact resists the heat transfer stronger than a 3 mm thick plate up to the load of 10 MPa (approximately 100 kg/cm2). The results show the importance of load control while measuring the thermal conductivity of materials. Otherwise, the contact resistance will significantly affect the received thermal conductivity coefficient values.

The thermal conductivity coefficient measurement

The thermal conductivity coefficient of copper is measured directly. No unique settings, no additional values, no other nonsence. Just insert your sample and enjoy the results!

Measuring the thermal conductivity of copper:

full video guide

The whole process, from the sample geometry measurements to the result evaluation,

takes less than 8 minutes!

Measurement of materials with low thermal conductivity

We have measured the thermal conductivity of air. It is between two copper plates in the photo. The first probe gave us k = 0.025 ± 0.0015 W/mK. The table value for 25 °C and one bar is 0.026 W/mK. With the new attachment, we can measure the thermal conductivity of all known materials, from air-gel to copper.

How we send thermal conductivity instruments.

Thermal conductivity is essential. The InoTherm system should safely go to our customer, so we put the device inside the soft box.

We are now closing the box with the InoTherm. The thermal conductivity measuring core and the equipment's electronic system will be safe here. The customer will enjoy easy unpacking and installing the thermal conductivity apparatus.

Our thermal conductivity coefficient measuring device, InoTherm, is ready for shipment to our customer. For accurate and dependable results in measuring composite material thermal conductivity, InoTherm is indispensable!

Thermal conductivity coefficient of polycarbonate

We measured the thermal conductivity coefficient of a polycarbonate sample at temperatures between 25 and 75 °C. It was k = 0.21 ± 0.005 W/mK within the temperature interval.

Thermal conductivity coefficient of polypropylene

The thermal conductivity coefficient of a polypropylene sample at temperatures between 25 and 40 °C. It was k = 0.24 ± 0.01 W/mK within the temperature interval. The sample diameter and thickness were 12.6 mm and 3.7 mm, respectively.

Thermal conductivity coefficient of graphite

We measured the thermal conductivity of MPG-7 graphite. The sample density was 1.83 g/cm3. The thermal conductivity coefficient k = 160 ± 4 W/mK.

Thermal conductivity coefficient of copper

The thermal conductivity coefficient of copper samples at temperatures between 25 and 40 °C was measured via direct heat flow evaluation, with a value of k = 392 ± 15 W/mK within the specified temperature interval. All the samples had a diameter of 9.8 mm. The thickness ranged between 4 and 11 mm.

Thermal conductivity coefficient of RS-pro thermopaste

We measured the thermal conductivity of RS-pro thermopaste at 60 °C. The measured thermal conductivity coefficient was k = 2.64 ± 0.1 W/mK. The value claimed by the manufacturer was 2.7 W/mK.

Please contact us to learn more about InoTherm

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.